Acoustic Design

A Magnetically Actuated Acoustic Metamaterial

by Thamarasee Jeewandara, Phys.org

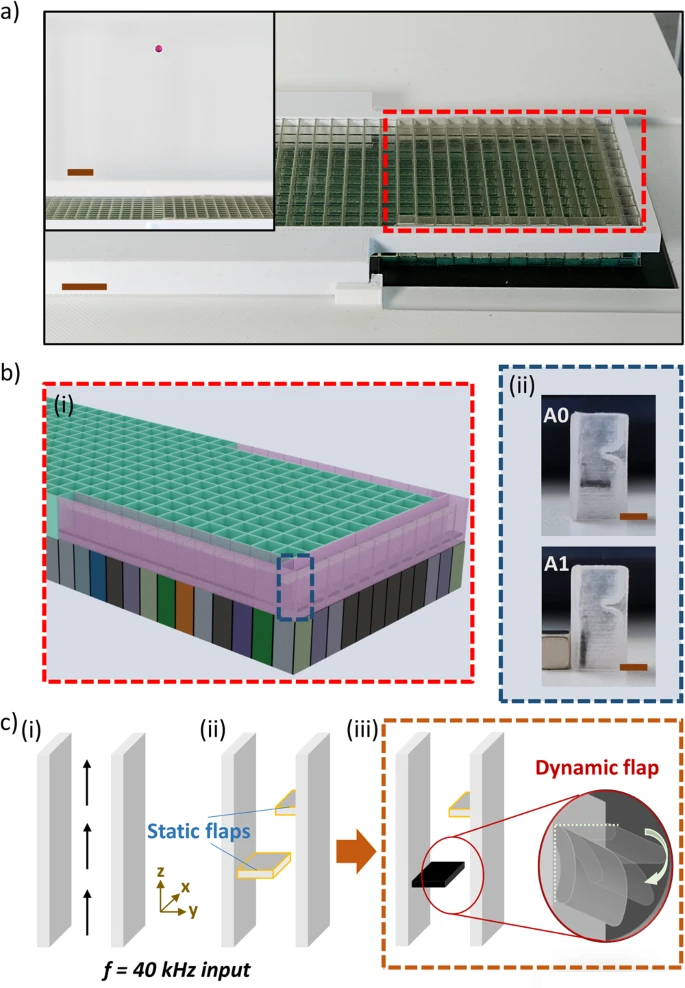

Space coiling acoustic metamaterials are static and require manual reconfiguration for sound-field modulation. In a new report published in Communications Materials, Christabel Choi, and a team of scientists in computer science and engineering in the U.K., and Italy, developed an approach for active reconfiguration with standalone dynamics to space-coil unit cells known as dynamic meta-bricks.

The meta-bricks housed an actuatable, magnetorheological, elastomeric flap, to function like a switch and to directly regulate the transmitted ultrasound. The scientists showed the synergy between active and passive reconfigurability to develop multifunctional metamaterials for design and implementation with additional degrees of freedom.

Smart materials

The current age of smart materials has seen the rise of metamaterials to innovate sound manipulation technologies. Schemes for reconfiguration have recently explored acoustic metamaterials to enhance complex wave-shaping applications, including acoustic levitation, cloaking, and holographic imaging.

Researchers can strategically regulate the physical shape and composition of a structure on demand to enable greater functional flexibility and deployment. To achieve real-time functionality, the scientists modulated the sound field upon actuation by using a transmissive acoustic metamaterial as a platform to explore the synergy between active and passive reconfigurability of a metasurface to achieve a modified output.

Engineering next-generation metamaterials

In this work, Choi and colleagues showed that a metasurface did not require a fully dynamic nature to generate a dynamic output. Conventionally, an active metasurface can be formed from a full array of actively reconfigurable unit cells with a high degree of electronic and computational complexity.

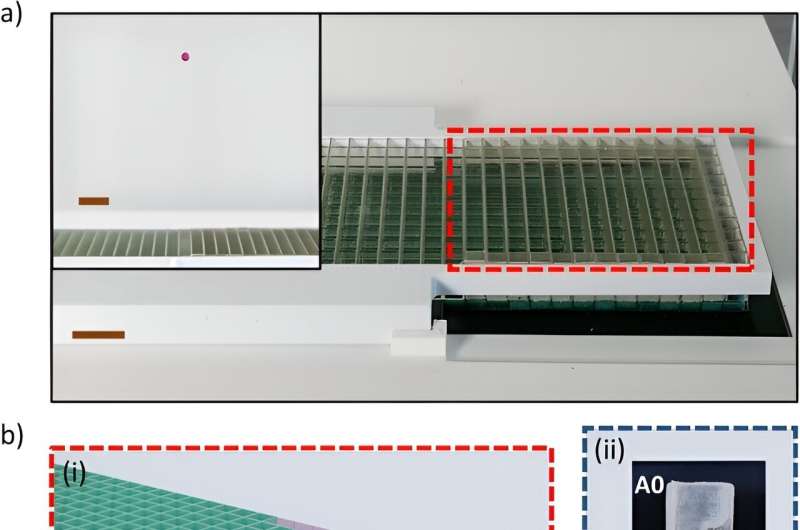

The scientists combined static and dynamic meta-bricks together to create hybrid meta-brick stacks within the metasurface. The researchers facilitated the dynamic meta-bricks to the edges of metasurfaces and magnetically regulated them to permit accurate sound modulation via simulations and experiments.

Sound engineers have thus far only achieved acoustic levitation with static metamaterials. The capacity to modulate ultrasound in real time has implications across a variety of domains including energy harvesting. Commercial audio applications can, for instance, use metamaterials to allow a narrow beam of sound to be directed dynamically to specific locations on demand. This work shows a method to engineer versatile, tunable, multifunctional, next-generation, metamaterials.

Designing the dynamic meta-brick

The presence of internal protuberances from the side walls in a meta-brick can create a labyrinth path for sound waves to travel through. While meta-bricks can be scaled to work at lower frequencies, the flaps can be designed to function at 40 kHz airborne ultrasonic frequency; suited for contactless manipulation and haptic feedback.

By using a magnetorheological elastomer, the team avoided conventional hinge-like mechanisms due to high amounts of associated friction, to achieve a maximum deflection angle for the meta-brick. The active binary flapping facilitated the path within the meta-brick to form a modifiable labyrinth to transfer acoustic waves in real time.

Manufacturing a dynamic meta-brick

Choi and colleagues developed a dynamic meta-brick where the external components referred to the meta-brick shell, and internal components referred to static and dynamic flaps of different lengths. The team developed the meta-brick shell along with the static and dynamic flaps via three-dimensional printing and molding methods.

For molding, the materials scientists used planar glass plates, developed using synthetic magnetic nanoparticles mixed with Ecoflex and cast within 3D printed molds.

They placed the molds over a magnet during the curing process and used a combination of washing and soaking at an elevated temperature to remove polymerization inhibitors. The team molded each flap with a consistent thickness and a coefficient of variation.

After assembling the dynamic meta-brick, they actuated it with a permanent magnet. Upon actuation, the flap rapidly moved towards the wall. In the presence of the magnetic field, the flap was sustained and stable, while when unactuated with a magnet, the flap remained in its original state.

Binary ultrasonic modulation, meta-bricks and metasurfaces

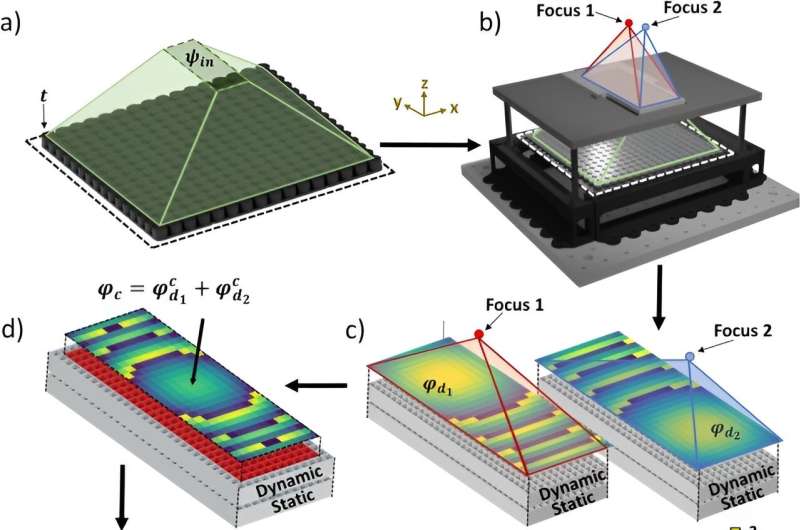

The team conducted simulations and experimental plots to show how combined actuation states affected the transmission in a small dynamic array; the results were in good agreement. While each meta-brick allowed a specific phase shift, the physically combined meta-bricks in a metasurface formed a combined phase shift as a collective acoustic output.

The researchers obtained a desired output sound field by predefining the phase values to determine the type of meta-brick required to assess their placement relative to each other.

By including a small number of locally actuated dynamic meta-bricks, they made an otherwise static global metasurface function dynamically. At first, they regulated the magnetic flap within the dynamic meta-brick and then assessed the meta-bricks within a metasurface via stacking. While the static stacks were formed due to placing a static meta-brick on top of another similar structure, dynamic stacks combined the two to create a vertical supercell.

Dynamic acoustic levitation

Cho and colleagues conducted pressure measurements by actuating and un-actuating the metasurfaces to visualize real-time modulation of the sound field. They devised twin composite stacked metasurfaces to demonstrate and contain the focused beams. The balance of acoustic pressure within these containments could tweeze the objects at low acoustic pressure regions.

For experimental validation, the research team shifted a lightweight polystyrene bead between the twin compartments. Upon actuation, the bead did not drop, to indicate how the fast-paced sound field modulation could maintain acoustic levitation.

Outlook

In this way, Christabel Choi and team introduced dynamic meta-bricks as a paradigm to design dynamic acoustic metamaterials that have emerged at the forefront of innovation for sound manipulation technologies. Materials scientists have keenly explored the niche to enhance complex wave-shaping applications, including acoustic levitation, cloaking, beam-steering, and holographic imaging.

By including a small, dynamic magnetic flap, the scientists transformed a static meta-brick into a dynamic construct, and combined the two to produce more than one output as a dynamic metasurface. The outcomes may pave the way for more sophisticated designs.

The team explored the experimental results with a theoretical model and via COMSOL Multiphysics simulations to show their excellent agreement. Such actuators can be functionalized, patterned, or coated to provide additional functionalities for fluidic systems and valves. These interdisciplinary approaches may pave the way to develop the next generation of metamaterials.